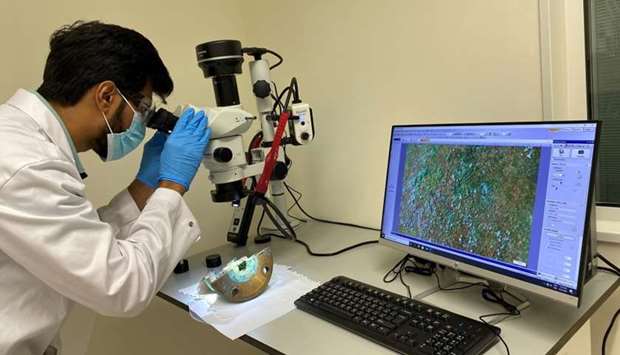

The Qatar Environment and Energy Research Institute (QEERI) at Hamad Bin Khalifa University (HBKU) is setting up a state-of-the-art corrosion testing facility that simulates oil and gas field conditions.

The facility, under the institute’s Corrosion Centre, will enable the testing of different types of material under diverse operating conditions, including flow conditions, operating temperatures, and pressures, plant start up, and sudden shutdown. In addition, the centre provides test programmes for pipeline integrity management, stress corrosion cracking, soil corrosion evaluation, marine corrosion, coating evaluation, and corrosion inhibitor evaluation.

The QEERI Corrosion Centre is currently engaged in four oil and gas industry-based projects, namely a study of localised corrosion and sulfide stress cracking of carbon and low alloy steels in hydrogen sulphide containing environments, evaluation of coating durability in three different geological locations; corrosion under insulation monitoring, and preventing and monitoring microbiologically influenced corrosion. While some are field studies, others are conducted in the lab under simulated field conditions.

“What makes our work unique is that we can design and customise our test setups to produce environments that mimic what exactly is in the field. Sometimes, we do large-scale testing to bring every aspect into the equation when we try to find corrosion solutions, and that is where we add value to industry stakeholders.

“All of our research projects are market-driven and aim to solve corrosion and materials engineering challenges facing Qatar’s industry. Recently, the centre started a programme focusing on the corrosion of reinforced concrete structures to expand our service to urban infrastructure sustainability in Qatar,” said Dr Hanan Farhat, senior research director, Corrosion Centre, QEERI.

In addition to its research activities, the QEERI Corrosion Centre supports industry by providing technical consultations and service, including fitness-to-service evaluation, corrosion risk assessment, root-cause-failure analysis, corrosion management planning, and advice on material selection.

The centre’s approach is to turn every corrosion challenge into research, development, and innovation projects where scientific knowledge along with industrial experience combine to provide customised solutions, and generate more knowledge, science and technology.

Material selection and corrosion are two major challenges faced by the oil and gas industry in the Middle East. The region’s unique environment of high temperatures, sandstorms, and high humidity in parts of the year make it difficult for engineering alloys to resist corrosion. There is still a need for comprehensive research studies to determine safe limits for engineering alloys in this environment.

Dr Marc Vermeersch, QEERI’s executive director, said: “Corrosion is similar to a cancer to our infrastructures, most of the time not highly visible in its early stages, while threatening asset integrity and financial sustainability or profitability of our companies; early diagnostic is therefore needed in order to identify adequate treatment and protect high-value assets in the country and beyond.

“Our Corrosion Centre aims to provide services, recommendations and solutions to further enhance and strengthen the oil and gas industry in the country. In line with Qatar National Vision 2030 and the Qatar National Research Strategy, QEERI’s mandate is to assist Qatar in tackling grand challenges related to energy, water, and the environment. Our aim is to secure the sustainability of industrial infrastructures in Qatar and reduce the cost of corrosion by providing the right solutions.”

Since its launch in 2019, the Corrosion Centre has been committed to engaging and working closely with stakeholders in Qatar to determine industry needs and provide technical and research support in the area of corrosion and materials engineering.

The QEERI Corrosion Centre is currently engaged in four oil and gas industry-based projects, namely a study of localised corrosion and sulfide stress cracking of carbon and low alloy steels in hydrogen sulphide containing environments, evaluation of coating durability in three different geological locations; corrosion under insulation monitoring, and preventing and monitoring microbiologically influenced corrosion. While some are field studies, others are conducted in the lab under simulated field conditions.

“What makes our work unique is that we can design and customise our test setups to produce environments that mimic what exactly is in the field. Sometimes, we do large-scale testing to bring every aspect into the equation when we try to find corrosion solutions, and that is where we add value to industry stakeholders.

“All of our research projects are market-driven and aim to solve corrosion and materials engineering challenges facing Qatar’s industry. Recently, the centre started a programme focusing on the corrosion of reinforced concrete structures to expand our service to urban infrastructure sustainability in Qatar,” said Dr Hanan Farhat, senior research director, Corrosion Centre, QEERI.

In addition to its research activities, the QEERI Corrosion Centre supports industry by providing technical consultations and service, including fitness-to-service evaluation, corrosion risk assessment, root-cause-failure analysis, corrosion management planning, and advice on material selection.

The centre’s approach is to turn every corrosion challenge into research, development, and innovation projects where scientific knowledge along with industrial experience combine to provide customised solutions, and generate more knowledge, science and technology.

Material selection and corrosion are two major challenges faced by the oil and gas industry in the Middle East. The region’s unique environment of high temperatures, sandstorms, and high humidity in parts of the year make it difficult for engineering alloys to resist corrosion. There is still a need for comprehensive research studies to determine safe limits for engineering alloys in this environment.

Dr Marc Vermeersch, QEERI’s executive director, said: “Corrosion is similar to a cancer to our infrastructures, most of the time not highly visible in its early stages, while threatening asset integrity and financial sustainability or profitability of our companies; early diagnostic is therefore needed in order to identify adequate treatment and protect high-value assets in the country and beyond.

“Our Corrosion Centre aims to provide services, recommendations and solutions to further enhance and strengthen the oil and gas industry in the country. In line with Qatar National Vision 2030 and the Qatar National Research Strategy, QEERI’s mandate is to assist Qatar in tackling grand challenges related to energy, water, and the environment. Our aim is to secure the sustainability of industrial infrastructures in Qatar and reduce the cost of corrosion by providing the right solutions.”

Since its launch in 2019, the Corrosion Centre has been committed to engaging and working closely with stakeholders in Qatar to determine industry needs and provide technical and research support in the area of corrosion and materials engineering.