By Shane Hickey/Guardian News and Media

There was a surge in the sale of electric cars last year but the number leaving the forecourts is still dwarfed by traditional gas-guzzlers at a ratio of almost 50 to one. The high cost of the batteries which power the vehicles is one prime reason.

Sheffield-based Faradion believes it has found a solution through a new type of battery technology, the development of which has been spearheaded in the UK.

“For an electric car, the cost of a battery is crudely the same as the cost of the rest. That is quite the wrong proportion for it to take off. So people are desperate to find ways to supply cheaper batteries,” chairman Chris Wright said.

In 2010, Wright and some colleagues pondered why large batteries used for electric cars and for energy storage from solar panels in the home were so expensive. The problem lay in the materials used to make them - specifically, those that contain lithium, of which there is a scarcity that drives up price.

Wright said “we would be on to a winner” if his team could find a material which contained a comparable but less expensive material to make the equivalent of lithium-ion batteries like those used in mobile phones.

The answer, they thought, was by using sodium which has a similar chemistry to lithium. The base materials needed to produce a sodium-ion battery are significantly easier to source than those for lithium-ion batteries.

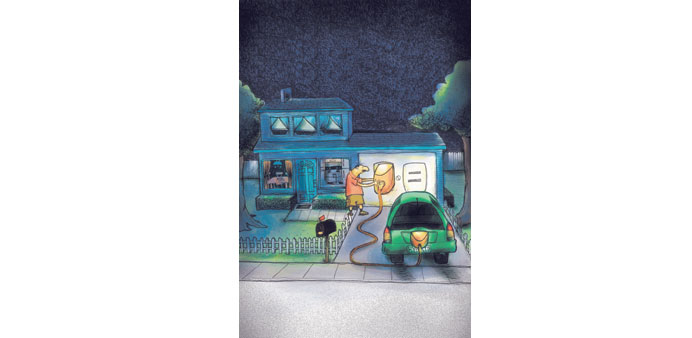

The market for systems which use large-scale batteries is expected to blossom in coming years as demand grows for home storage units for the energy generated from solar panels as well as in electric cars. This in turn has led to the pursuit within the industry of ever cheaper alternatives in battery technology.

“We set out to make sodium materials that worked in a simple electrochemical (battery) cell that behaved as well as if not better than some of the lithium systems. We were able to produce material which outperformed lithium-ion phosphate, which has until recently been the workhorse in automotive batteries.”

Last May Faradion unveiled what it claims to be one of the most advanced sodium-ion batteries on the market, which costs some 30% less than a lithium-ion equivalent. The company demonstrated its research and development at the headquarters of Williams Advanced Engineering in Oxfordshire using an e-bike which was powered by the new technology.

To the casual observer, the battery looks and performs in the same way as a regular lithium-ion battery but the materials used are cheaper to source. In theory, this could in turn lead to savings in the cost of cars and home battery storage units.

Another benefit exists in the transport of the new batteries, said Wright. Strict guidelines surround the transport of lithium-ion batteries because they can cause explosions if they short circuit.

Last month Boeing warned passenger airliners against carrying bulk shipments of lithium-ion batteries in their cargo as they could cause fires.

The sodium-ion batteries do not have the same problem, Wright argued, meaning they could be transported more quickly and easily without the safety concerns and the logistical costs.

The benefit to consumers in using the cheaper batteries is that goods such as electric cars and energy storage units could now fall in price, he said.

“Things will become available which weren’t available before. People are very frequently annoyed with their batteries,” Wright said. “Battery performance has really lagged behind the ambition and vision of people who are making other products. There is a lot of potential for batteries which tick the right boxes.”

After starting in the area with relatively few players, the sector is now booming, said Wright. For Faradion, the focus is now on trying to licence out their technology.

The problem with getting the battery technologies into cars is that it can take eight years from when the deal is done to vehicles going on sale, Wright said. For energy storage units however, the technology could be installed much quicker.

Home energy generation has blossomed in the UK over the past four years, with an estimated 670,000 homes fitted with solar panels. Companies such as Elon Musk’s Tesla aim to capitalise on this trend with the “Powerwall” home energy storage batteries and a planned “gigafactory” in Nevada which will be the largest producer of lithium-ion batteries in the world by 2017.

This is expected to force other battery manufacturers to seek alternatives in case they are priced out of the market - which is where Faradion aims to come in.

“They (the other battery producers) are a natural target for us because they can use our materials and reduce their materials cost and find themselves able to compete with Tesla who have a large-scale plant,” Wright said.

A decade ago, solar panels for the home were prohibitively expensive but the reduction in costs now mean they have proliferated. “I can see the same thing happen with energy storage,” he said.

The Society of Motor Manufacturers and Traders (SMMT) said that sales of alternatively-fuelled vehicles (AFVs) - including electric cars and hybrids - rose by 58% in 2014, with 51,739 new AFVs registered. AFV sales accounted for a market share of 2.1% in 2014 - up from 1.4% a year earlier.

The market for systems which use large-scale batteries is expected to blossom in coming years as demand grows for home storage units for the energy ge