A lab in the US is working on ideas for future vehicles, to cut fuel

use and reduce weights to improve efficiencies. By Mark Phelan

Nestled in the rolling Tennessee hills and forests, the secretive lab that developed power for the Manhattan Project is working to change the auto industry and reduce US dependence on foreign fuel.

Projects under way at Oak Ridge National Laboratory include:

1) An oil additive that may reduce any vehicle’s fuel consumption at least 2 percent and cut US oil consumption by billions of gallons a year.

2) A way to slash the cost of carbon fibre so everyday cars and trucks can use the strong, light material that’s currently reserved for exotic sport cars.

3) A charging system to eliminate the batteries that currently account for much of electric cars’ cost and weight.

The labs and research centres here have worked with the auto industry since the energy crises of the 1970s and 1980s. Oak Ridge helped develop materials, fuels and systems used by millions of vehicles.

The Department of Energy has final approval over all projects with private companies, said Ron Graves, director of the lab’s sustainable transportation programme.

Here’s some of what’s in the works:

MAKING OIL MORE SLIPPERY

The oil additive Oak Ridge developed could be the poster child for government research. Senior research scientist Jun Qu worked on it for 10 years, longer than a private company would likely support a project, but the result is a low-cost additive that appears to reduce the fuel consumption of any engine at least 2 percent. That would amount to two billion gallons of fuel a year, a massive decrease in emissions and US energy imports.

Qu tested the liquid additive with General Motors, Shell Oil and Lubrizol.

“This technology holds tremendous potential,” said Michael Viola, the GM staff research engineer who tested the lubricant at the automaker’s Tech Center in Warren, Mich. “We’re very pleased GM is working hard to improve the fuel economy and emissions of our vehicles. This is exactly what we wanted.”

Qu said the additive reduces the oil’s viscosity with no increase in engine wear. Even greater improvements in fuel economy are possible by combining it with other additives already in use, he said.

Oak Ridge will license production to industry, said Jennifer Tonzello Caldwell of the lab’s technology transfer division.

“We give preferential licensing to small US companies, if they have the wherewithal to produce it,” Caldwell said. “We want job creation in the United States.”

The laboratory will get a royalty from production, like universities do when their discoveries are commercialised.

“GM is pushing to have the additive produced,” Qu said. “It could be in production within five years.”

AFFORDABLE CARBON FIBRE

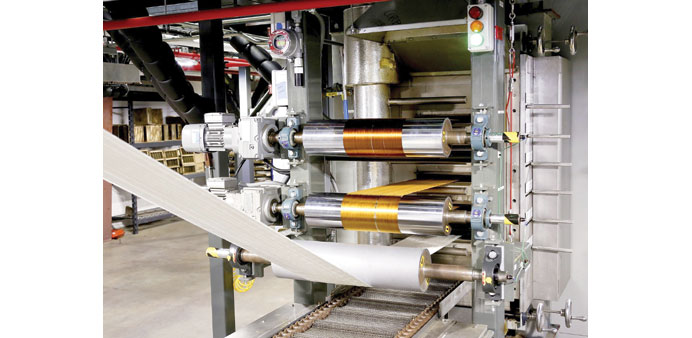

A new process to make carbon fibre could cut the exotic lightweight material’s cost nearly 50 percent.

“We’re exploring lower-cost raw material to move carbon fibre from niche vehicles to the mass market,” said Lee McGetrick, director of Oak Ridge’s carbon fibre technology centre.

The centre has cut the cost to $7 a pound from $12 a pound today in cars like the $1.4-million La Ferrari. The centre is working with supplier Faurecia and the Composite Vehicle Research Center at Michigan State University to get carbon fibre into wider production.

“This material has a lot of promise in mass production,” said Mahmoodul Haq, Michigan State assistant professor of mechanical engineering. “The Oak Ridge fibre makes it easier and to manufacture parts. Carbon fibre has been a rich man’s game. The fibre from Oak Ridge and the new machine can change that.”

WHO NEEDS BATTERIES?

Oak Ridge has developed a system that makes inductive charging, which charges batteries without physically connecting to an outlet, as efficient as charging through a plug, said Madhu Chinthavali, team leader of Oak Ridge’s power electronics group.

“We’re working on dynamic wireless charging,” where the charging coils are buried in the road and the car doesn’t need expensive batteries to store electricity, Chinthavali said. That would cut the cost and energy consumption of electric vehicles radically.

The lab is also developing electric motors that don’t use rare-earth minerals. The US is dependent on other countries, primarily China, for most rare earths.

“Our goal is to get these technologies into the world so the taxpayers benefit,” he said. “Show the technologies to automakers and let them adapt it to their needs.”

Oak Ridge is also the largest domestic battery lab. It’s developing less-expensive, more-powerful batteries for electric cars.

“We don’t want to be dependent on importing battery technology in a similar way we are dependent on importing foreign oil,” said David Wood, fuel cell technologies programme manager. “We need to build up our manufacturing processes and materials supply chain here in the US so that we don’t have to import batteries from Asia.” — Detroit Free Press/MCT